Foreign Object Contamination in Food

The Hidden Risk Costing Brands Millions — And How to Prevent It

Foreign object contamination in food manufacturing is one of the most significant and costly challenges facing the industry today. From tiny metal fragments to stray bits of plastic, foreign objects can trigger food recalls that damage brand reputation, risk consumer safety, and cost businesses millions.

At Pinnacle Management Systems, we help food businesses take control of foreign object risks through practical training, templates, and food safety management systems. Here’s why proactive management is essential—and how you can stay ahead.

What Is Foreign Object Contamination?

Foreign object contamination occurs when unintended items enter food products during manufacturing, processing, or packaging. These objects can include:

- Metal shavings from equipment

- Plastic fragments from packaging

- Wood splinters from pallets

- Stones, glass, or insects from raw materials

Even the smallest fragment can result in consumer injury, expensive recalls, and lasting brand damage.

Why Foreign Object Contamination Is a Pain Point for Food Manufacturers

Food manufacturers face enormous pressure to prevent foreign object contamination because:

1. Consumer safety is at stake: foreign objects can cause choking, injury, or dental damage, leading to lawsuits and regulatory action.

2. Standards like HACCP, BRCGS, SQF, and ISO 22000 require proactive foreign object control measures and meticulous documentation.

3. Recalls are expensive: the cost of a single recall can easily exceed six figures—or even millions—when you factor in:

- Product withdrawals

- Retailer penalties

- Legal costs

- Loss of consumer trust

- Negative publicity

4. Detection can fail without proper controls: many businesses rely on metal detectors or X-ray machines but fail to implement robust foreign object detection programs across their entire process.

How Foreign Objects Enter Food Production

Understanding where foreign objects originate helps businesses prevent them. Common sources include:

- Equipment wear and tear (metal fragments)

- Packaging damage (plastic or cardboard pieces)

- Poor raw material handling (stones, insects)

- Manual errors (dropped tools, personal items)

Each step in the process - from receiving ingredients to final packaging - presents potential contamination risks.

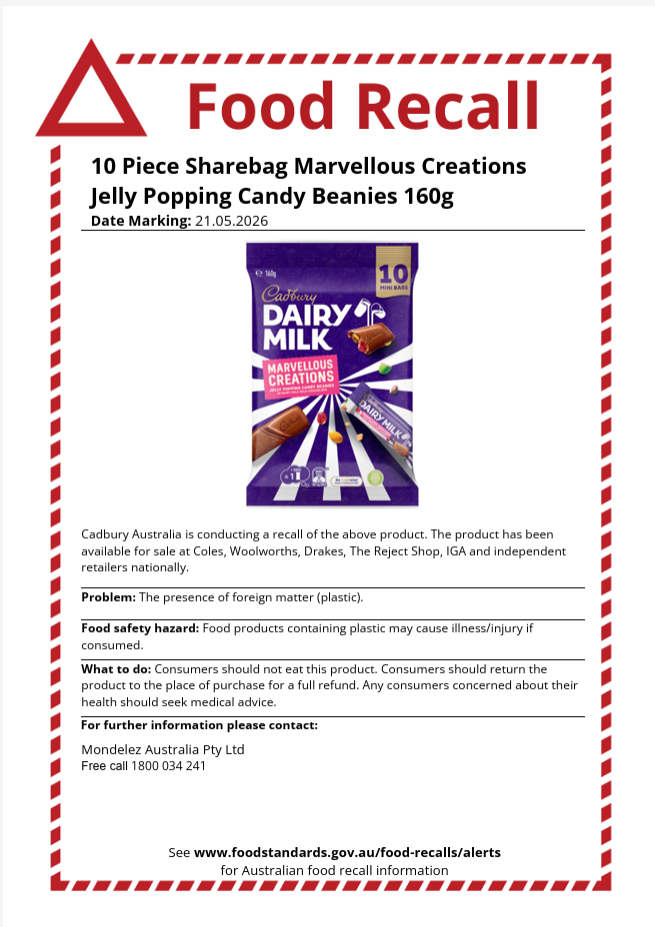

The Real Cost of Food Recalls

Foreign object contamination isn’t just a quality defect—it’s a business crisis. Recent recalls like the Picnic Point Farm Orchard Fresh Raspberry Jam (recalled due to metal fragments) highlight how quickly issues escalate. Costs include:

- Product retrieval and destruction

- Logistics and admin costs

- Loss of retailer shelf space

- Damage to reputation and future sales

- Legal action from injured consumers

According to the Food Marketing Institute, the average cost of a food recall in the U.S. is $10 million, or $15 million Australian dollars excluding brand damage.

Why Food Businesses Need Foreign Object Control Templates and Training

Many food businesses struggle because they lack systematic foreign object prevention measures. Common gaps include:

- Incomplete or inconsistent foreign object control records

- Staff unaware of contamination risks

- Poorly documented corrective actions

- Inadequate validation of detection equipment

Pinnacle Management Systems bridges these gaps with solutions designed for the food industry:

Pinnacle’s Foreign Object Control Templates

Our Foreign Object Control Templates are practical tools that help you:

- Map foreign object risks in your process flow

- Document preventive controls

- Maintain audit-ready records for regulators and customers

- Standardise foreign object checks and corrective actions

Training for Food Safety Teams

We offer training that for food safety teams that is practical, based on experience from our certified auditors and consultants.

Why Proactive Foreign Object Control Protects Your Brand

Preventing foreign object contamination is more than compliance; it’s about protecting your customers, your brand, and your bottom line.

Proactive foreign object management is the best defence against expensive recalls and reputational harm.

Take Action Now

Don’t wait for a foreign object incident to put your brand in the headlines for the wrong reasons. Get the tools, training, and expert guidance you need to keep your products safe.

Explore Pinnacle Management Systems’ foreign object control templates and training today.