Mould Contamination in Packaged Food

How It Happens and How to Prevent It

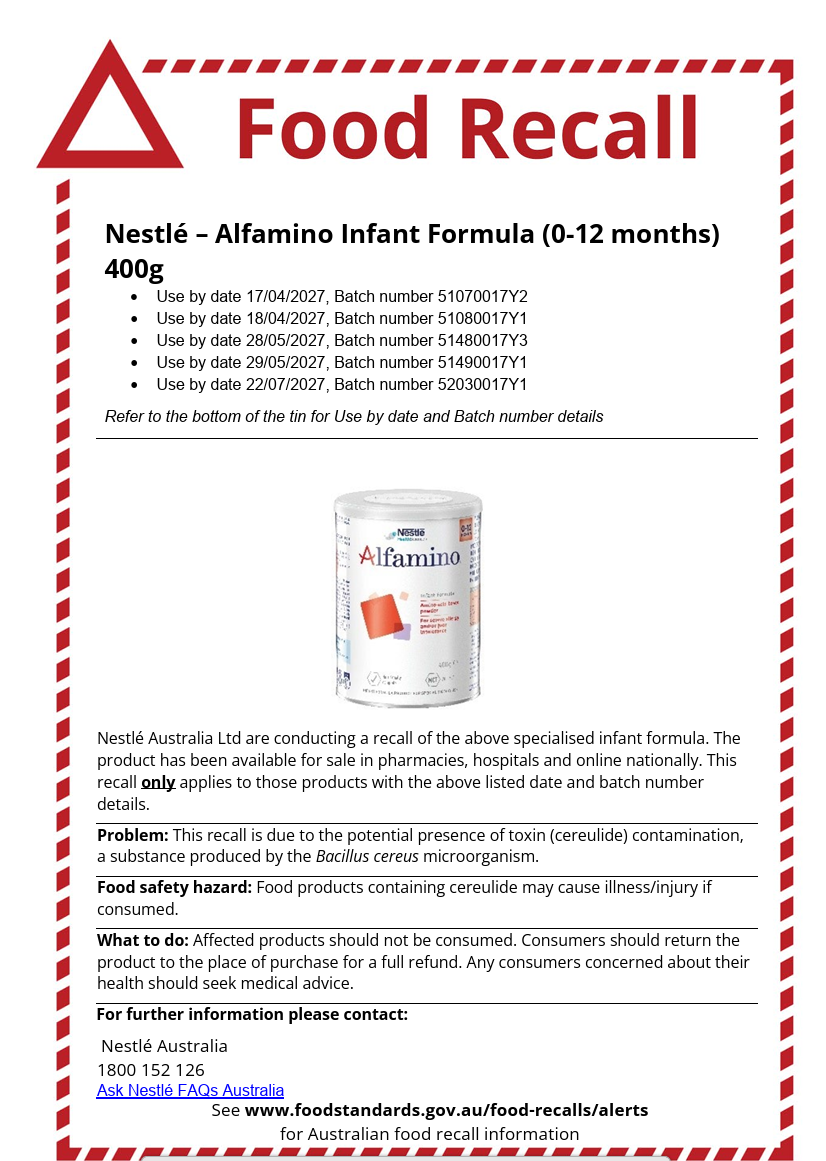

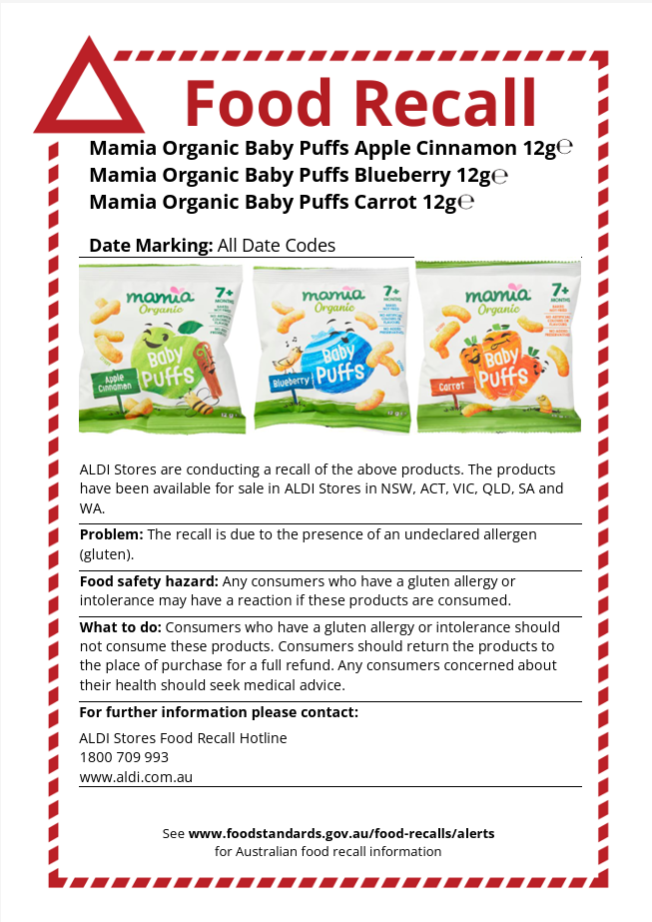

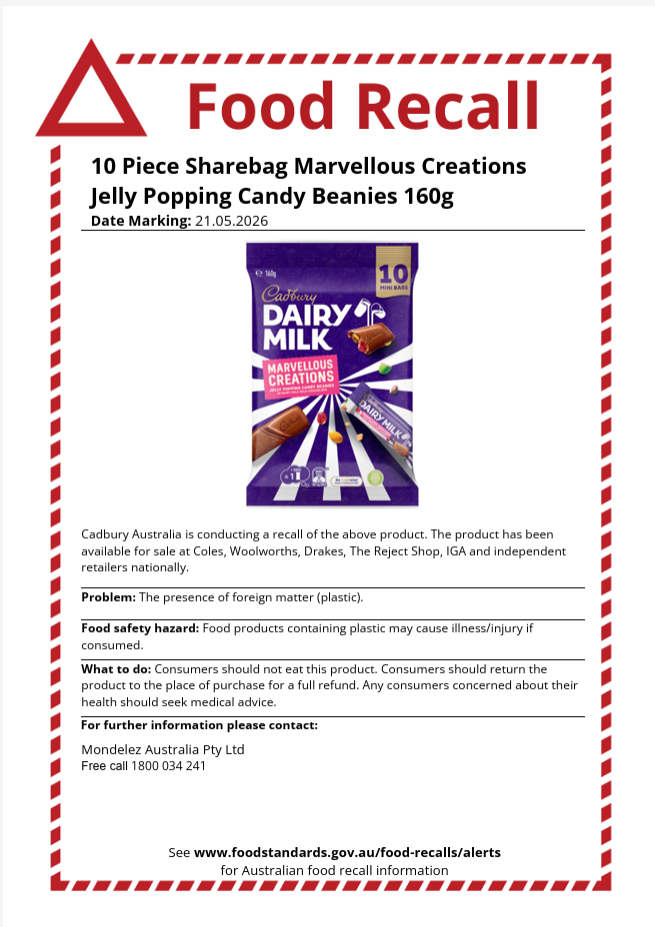

When consumers open a sealed product and discover mould, trust is broken—and so is compliance. Mould contamination is common but preventable cause of food recalls in Australia. In many cases, the root cause lies not with the food itself, but with the packaging.

So how does packaging failure lead to mould? And what can food businesses do to prevent it?

How Mould Contamination Happens Due to Packaging Faults

Packaging serves as the final barrier between a food product and its environment. When it fails, microorganisms like mould spores find an opportunity to thrive. Here are some key ways packaging faults contribute to mould growth:

1. Compromised Seal Integrity

If heat-sealing machines are misaligned or the temperature is inadequate a complete seal may not be achieved, even a microscopic gap can allow moisture and oxygen to enter—creating ideal conditions for mould.

2. Inadequate Packaging Material

Using packaging that is not moisture or oxygen-resistant for high-risk products (like dried meats, cheeses, or ready-to-eat meals) increases the likelihood of spoilage.

3. Contamination During Packing

Mould spores present in the air, on surfaces, or inside packaging can contaminate the product before sealing, particularly if packaging takes place in a poorly controlled environment.

4. Storage & Transport Conditions

Even with good packaging, excessive humidity, condensation, or temperature fluctuations during distribution can lead to packaging deterioration and mould growth.

How Food Businesses Can Prevent Mould Contamination

1. Review Packaging Specifications

Ensure that your packaging material is fit for purpose. Consider the moisture barrier, oxygen transmission rate (OTR), and compatibility with your product’s shelf life.

2. Validate and Monitor Sealing Processes

Regularly test seal integrity with burst or bubble tests, and conduct equipment checks and calibration to ensure heat sealers and vacuum packaging units are functioning correctly.

3. Maintain High Hygiene Standards in Packing Areas

Packing areas should be regularly cleaned and monitored for airborne contaminants. Use filtered airflow, especially when dealing with high-risk foods.

4. Implement Environmental Monitoring Programs

Test for mould and other microbial contamination on surfaces, equipment, and in the air, particularly in high-risk zones.

5. Conduct Shelf-Life and Challenge Testing

Validate your packaging under real and accelerated conditions to confirm it can preserve the product through its intended shelf life.

6. Train Staff in Packaging Hygiene and Fault Identification

Operators and QA teams should be trained to identify early signs of packaging failure or improper sealing.

7. Audit Your Supply Chain

Packaging materials should come from approved suppliers with documented quality assurance and food safety. Check that they meet your food safety specifications consistently.

Be Proactive, Not Reactive

In recent food recall cases—including those due to visible mould growth in vacuum-packed meat and chilled RTE products—investigations often trace the issue back to avoidable packaging failures. While recalls are costly, the greater cost is often damage to brand reputation and loss of customer trust.

Need Help?

At Pinnacle Management Systems, we empower food businesses with:

- Packaging and food safety risk assessments

- HACCP plan updates and packaging validations

- Internal audits and root cause analysis

- Training on shelf-life control, hygiene, and GMP

- Supplier approval, monitoring and supply chain audits

- Custom templates and checklists tailored to your product type and standards (HACCP, ISO 22000, BRC, SQF, FSSC)

Book a consultation or explore our compliance tools on our website.