Unlocking Food Safety: The Ultimate Guide to HACCP Templates for Your Business

In today’s fast-paced food industry, ensuring safety and compliance is more critical than ever. Unlocking food safety through a robust Hazard Analysis and Critical Control Points (HACCP) plan is essential for protecting your business and gaining the trust of your customers. With increasing regulations and heightened consumer awareness, implementing the right HACCP templates can streamline your processes, strengthen food safety measures, and keep your operations running smoothly. This ultimate guide will walk you through the essentials of HACCP templates tailored for your business needs. Whether you’re a small food producer or a large-scale manufacturer, this resource offers a comprehensive roadmap to navigate the complexities of food safety management. Join us as we explore the key components of effective HACCP templates and empower your team to establish a culture of safety that resonates with quality and compliance. Let’s dive into the world of HACCP and unlock the potential for a safer, more successful food business!

Understanding HACCP: What It Is and Why It Matters

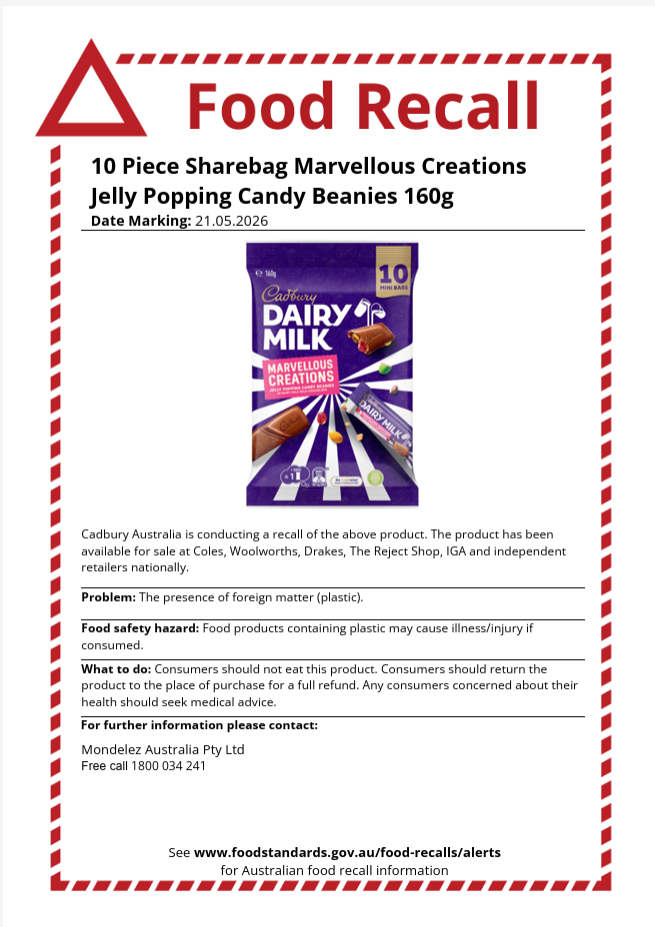

Hazard Analysis and Critical Control Points (HACCP) is a systematic approach to food safety that focuses on preventing hazards that could cause foodborne illnesses. It involves identifying, evaluating, and controlling hazards at every stage of the food production process, from raw material production to consumption. The HACCP system is internationally recognised and provides a structured methodology for managing food safety risks, ensuring that food products are safe for human consumption. This approach not only protects consumers but also helps businesses avoid costly recalls and legal issues.

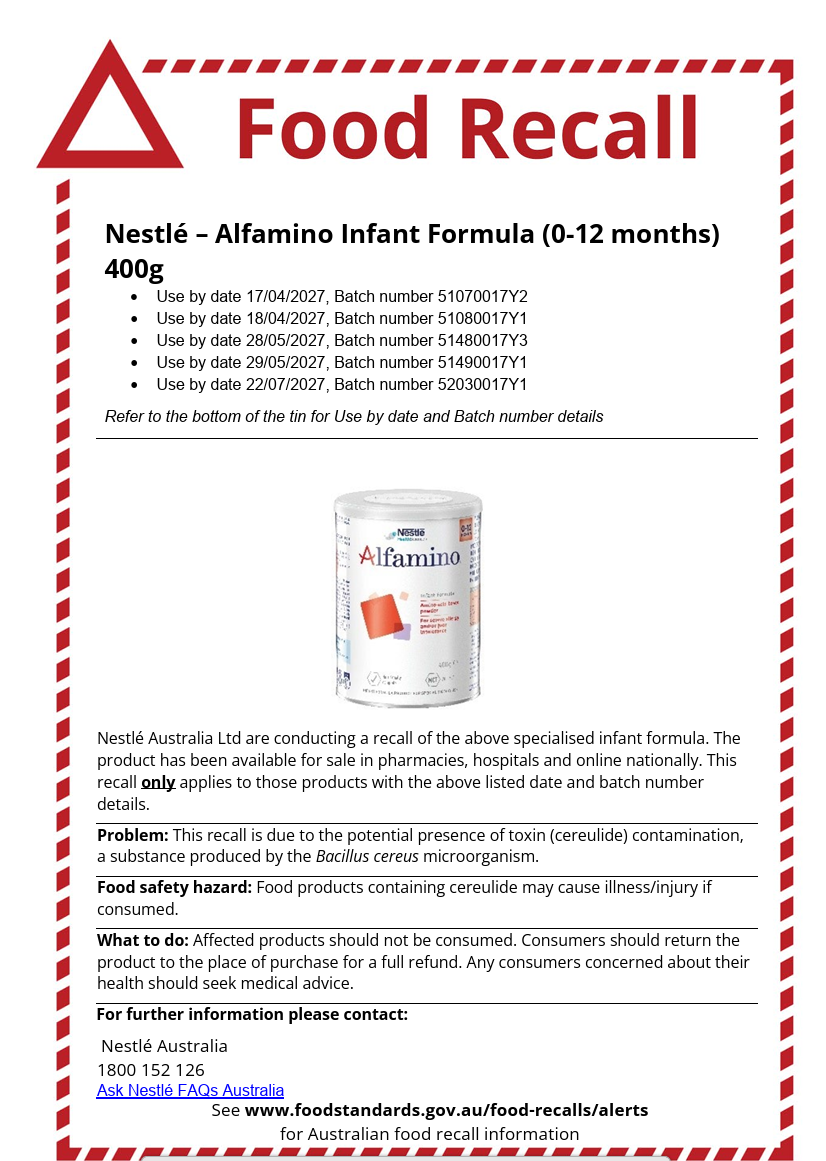

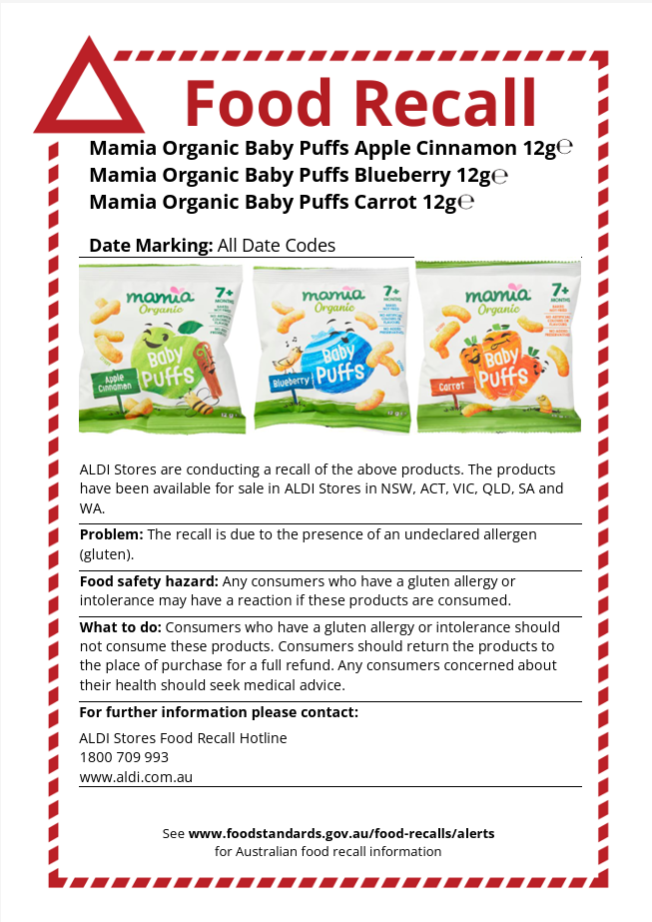

The importance of HACCP cannot be overstated in today’s food industry. With the increasing complexity of food supply chains and the globalisation of food markets, the potential for contamination and foodborne illnesses has grown. A well-implemented HACCP plan helps businesses mitigate these risks by identifying critical points in the production process where hazards can be controlled. By focusing on prevention rather than detection, HACCP minimises the chances of harmful incidents occurring, thereby safeguarding public health.

Moreover, adherence to HACCP principles is often a legal requirement. Regulatory bodies around the world, such as Food Standards Australia New Zealand (FSANZ), mandate that food businesses implement HACCP systems. Compliance not only ensures that businesses meet legal obligations but also enhances their reputation and consumer trust. Customers are increasingly aware of food safety issues and prefer to purchase products from companies that prioritise their health and safety.

The Importance of Food Safety in the Food Industry

Food safety is a critical concern in the food industry, as it directly affects public health. Unsafe food can lead to foodborne illnesses, which may cause severe health issues and even death. According to the World Health Organization (WHO), an estimated 600 million people fall ill after consuming contaminated food each year, resulting in 420,000 deaths. These statistics highlight the urgency of implementing robust food safety measures to protect consumers.

For businesses, food safety is not just a regulatory requirement but also a key component of operational integrity. A single food safety incident can have devastating consequences, including loss of customer trust, legal action, and financial losses. In severe cases, businesses may face closure. Therefore, maintaining high food safety standards is essential for the sustainability and success of any food-related enterprise. It helps in building a loyal customer base, enhancing brand reputation, and ensuring long-term profitability.

Additionally, food safety is crucial for maintaining the quality of food products. Contaminants can affect the taste, texture, and nutritional value of food, leading to inferior products that do not meet consumer expectations. By implementing effective food safety practices, businesses can ensure their products consistently meet quality standards, which is vital for customer satisfaction and retention. In a competitive market, food safety and quality are significant differentiators that can set a business apart from its competitors.

Key Principles of HACCP

The HACCP system is built on five steps and seven fundamental principles that provide a framework for managing food safety.

The 5 Steps are often used to organise the process of developing a HACCP plan before applying the seven principles:

- Assemble the HACCP Team

- Gather a multidisciplinary team with knowledge of the product and process.

- Describe the Product

- Clearly define the food/product, its ingredients, processing methods, packaging, storage, and distribution.

- Identify Intended Use and Consumers

- Specify how and by whom the product will be used (e.g., general public, hospitals, children).

- Construct a Process Flow Diagram

- Map out every step in the process, from receiving ingredients to final product delivery.

- On-site Confirmation of Flow Diagram

- Walk through the process to verify the flow diagram matches actual operations.

After these five steps, you then apply the 7 HACCP principles to the mapped process.

- Hazard Analysis: Identify potential hazards that could affect food safety. Hazards can be biological, chemical, or physical, and it is essential to evaluate each one to understand its potential impact on the food production process.

- Determine Critical Control Points (CCPs): Identify stages in the food production process where control measures can be applied to prevent, eliminate, or reduce hazards to acceptable levels.

- Establish Critical Limits: Set the maximum or minimum values to which a hazard must be controlled at a CCP to prevent, eliminate, or reduce it to an acceptable level.

- Establish Monitoring Procedures: Develop procedures to ensure each CCP remains within its critical limits.

- Establish Corrective Actions: Determine actions to be taken when monitoring indicates that a CCP is not within the established critical limits.

- Establish Verification Procedures: Confirm that the HACCP system is working effectively.

- Establish Record-Keeping and Documentation: Maintain a written account of the HACCP plan and its implementation.

In summary:

- Five steps = Getting ready and setting up your HACCP plan.

- Seven principles = The rules you follow to actually manage food safety.

How to Create an Effective HACCP Plan

Creating an effective HACCP plan begins with assembling a knowledgeable HACCP team. This team should consist of individuals with expertise in various aspects of the food production process, including production, quality control, sanitation, and microbiology. The team is responsible for developing, implementing, and maintaining the HACCP plan. It is essential to ensure team members are adequately trained in HACCP principles and their application.

The next step is to describe the product and its intended use, including details of the ingredients, processing methods, packaging, storage, and distribution. Understanding the product and how it will be used by consumers helps identify potential hazards and determine appropriate control measures. The team should then construct a flow diagram that outlines each step of the production process. The flow diagram serves as a visual representation of the process and helps identify critical control points.

Once the flow diagram is complete, conduct a hazard analysis to identify potential hazards at each step of the process. This involves evaluating the likelihood and severity of each hazard and determining which ones need to be controlled. After identifying hazards, determine critical control points and establish critical limits for each CCP. Monitoring procedures, corrective actions, verification procedures, and record-keeping practices should also be established. Regular reviews and updates to the HACCP plan are necessary to ensure its continued effectiveness.

Essential Components of HACCP Templates

HACCP templates are invaluable tools that help streamline the creation and implementation of a HACCP plan. These templates typically include several essential components:

- Hazard Analysis Template: Guides the team through the process of identifying and evaluating potential hazards.

- CCP Decision Tree Template: Helps determine which steps in the production process are critical control points.

- Monitoring and Corrective Action Templates: Document the procedures used to ensure each CCP remains within its critical limits and guide the team in implementing corrective measures when necessary.

Customising HACCP Templates for Your Business Needs

While generic HACCP templates provide a solid foundation, customising them to suit your specific business needs is crucial for their effectiveness. Each food business is unique, and the hazards and control measures applicable to one may not be relevant to another. Customisation begins with a thorough understanding of your production process, including the ingredients used, processing methods, and the specific risks associated with your products.

Start by reviewing the generic templates and identifying areas that require modification. For example, a bakery will have different hazards and critical control points compared to a meat processing facility. Adjust the hazard analysis template to include specific hazards relevant to your product. Customisation ensures the HACCP plan is tailored to address the specific risks and requirements of your business.

Engage your HACCP team in the customisation process. Their expertise and knowledge of the production process are invaluable in identifying relevant hazards and determining appropriate control measures. Regularly review and update the customised HACCP templates to reflect changes in the production process, new regulatory requirements, or emerging food safety risks. Keeping the templates up to date ensures your HACCP plan remains effective in managing food safety risks.

Common Challenges in Implementing HACCP and How to Overcome Them

Implementing a HACCP plan can be challenging, and businesses often face several common obstacles. One significant challenge is resistance to change. Employees may be accustomed to existing practices and may resist adopting new procedures. Overcoming this resistance requires effective communication and training. Educate employees about the importance of HACCP and how it benefits the business and consumers. Provide comprehensive training to ensure they understand their roles and responsibilities.

Another common challenge is the complexity of the HACCP system. Developing and implementing a HACCP plan involves detailed analysis and documentation, which can be overwhelming for some businesses. Simplify the process by breaking it down into manageable steps. Use HACCP templates to guide the development process and ensure all necessary components are included. Seek assistance from food safety consultants or industry experts if required.

Maintaining consistent implementation can also be challenging. Ensuring that monitoring, corrective actions, and verification procedures are consistently followed requires ongoing effort. Establish clear procedures and assign responsibilities to specific team members. Regularly review and audit the HACCP plan to identify any gaps or areas for improvement. Foster a culture of food safety within the organisation by encouraging open communication and continuous improvement.

Tools – How Pinnacle Management Systems Can Help

1. Gap Analysis Tools

- We systematically review your current food safety or quality management documentation against the latest Codex HACCP, ISO 22000, SQF or BRC or other retailer standards such as Woolworths, ALDI, Costco.

- You get a clear, actionable report highlighting what’s working, what’s missing, and exactly what needs to be improved for certification success.

2. Customisable Document Templates

- Access to 150+ ready-made food safety and quality management templates (including HACCP plans, policies, and procedures), all fully customisable in Word or Excel.

- Save time and ensure compliance; our templates are always up-to-date with current regulations and can be tailored to your specific business or industry.

3. Staff Training & Internal Auditing Programs

- Both online and in-person training for your team, including our most popular internal auditing courses.

- Build in-house expertise, boost staff confidence, and ensure your systems are robust and audit-ready at all times.

4. System Integration & Implementation Support

- We help you integrate quality, food safety, and environmental management systems seamlessly into your existing operations.

- Achieve certification efficiently, with minimal disruption and maximum alignment to your business needs.

5. Post-Certification Maintenance

- Ongoing support for internal audits, compliance checks, and system maintenance.

- Stay compliant year-round and be fully prepared for external audits—no last-minute scrambles.

6. Consultation & Audit Preparation

- Direct support from certified lead auditors with decades of experience, including help preparing for external audits.

- Increase your chances of first-time certification success (we have a 100% track record!) and reduce stress for your team.

7. Access to Industry Insights

- Share the latest industry updates, regulatory changes, and best practices via email and LinkedIn.

- Keep your business ahead of the curve and always informed about what matters most to your compliance.

Conclusion: Ensuring Compliance and Enhancing Food Safety Standards

Ensuring food safety is a critical responsibility for businesses in the food industry. Implementing a robust HACCP plan is an effective way to manage food safety risks, protect consumers, and comply with regulatory requirements. By understanding the principles of HACCP and utilising customised templates, businesses can create effective HACCP plans tailored to their specific needs.

Overcoming common challenges in HACCP implementation requires effective communication, training, and a commitment to continuous improvement. Utilising available tools, resources, and industry best practices can streamline the development and implementation process. Learning from successful HACCP implementations in various industries provides valuable insights and inspiration for enhancing food safety standards.

Ultimately, a well-implemented HACCP plan not only ensures compliance but also builds consumer trust and enhances the reputation of the business. By prioritising food safety, businesses can create a culture of quality and excellence that resonates with customers and drives long-term success. Unlocking food safety through HACCP is not just a regulatory requirement; it is a strategic advantage that sets businesses apart in a competitive market.

References

Food Standards Australia New Zealand (FSANZ) – HACCP Guidelines