January: The Strategic Moment to Reset Management System Objectives for 2026

Across ISO 9001, ISO 22000, ISO 14001, and ISO 45001

January is more than a calendar reset. For organisations operating ISO management systems, it is a critical governance milestone and a high-leverage opportunity to confirm that objectives across quality, food safety, environment, and work health and safety remain aligned, effective, and future-ready for 2026.

All standards including ISO 9001, ISO 22000, ISO 14001, and ISO 45001, require organisations to establish objectives that are consistent with policy commitments, measurable, monitored, communicated, and updated as appropriate. Yet in practice, objectives are often rolled forward with minimal challenge, gradually losing their relevance as business conditions, risks, and stakeholder expectations evolve.

January is the best time of the year to interrupt that cycle.

With a full year of operational data, incidents, audit outcomes, corrective actions, and management review inputs available, organisations are well positioned to assess whether their objectives are genuinely driving system performance or merely satisfying certification requirements.

Moving Beyond Compliance to Strategic

High-performing management system objectives are not isolated targets. They act as a translation mechanism between organisational strategy and day-to-day operations.

A structured January review should confirm that objectives across all standards:

- Directly support organisational strategy, growth plans, and risk appetite for 2026

- Reflect current regulatory, customer, and stakeholder expectations

- Address the most material risks and opportunities identified through context analysis

- Reinforce leadership commitments articulated in policy statements

For example:

- ISO 9001 objectives should strengthen customer satisfaction, consistency, and process effectiveness

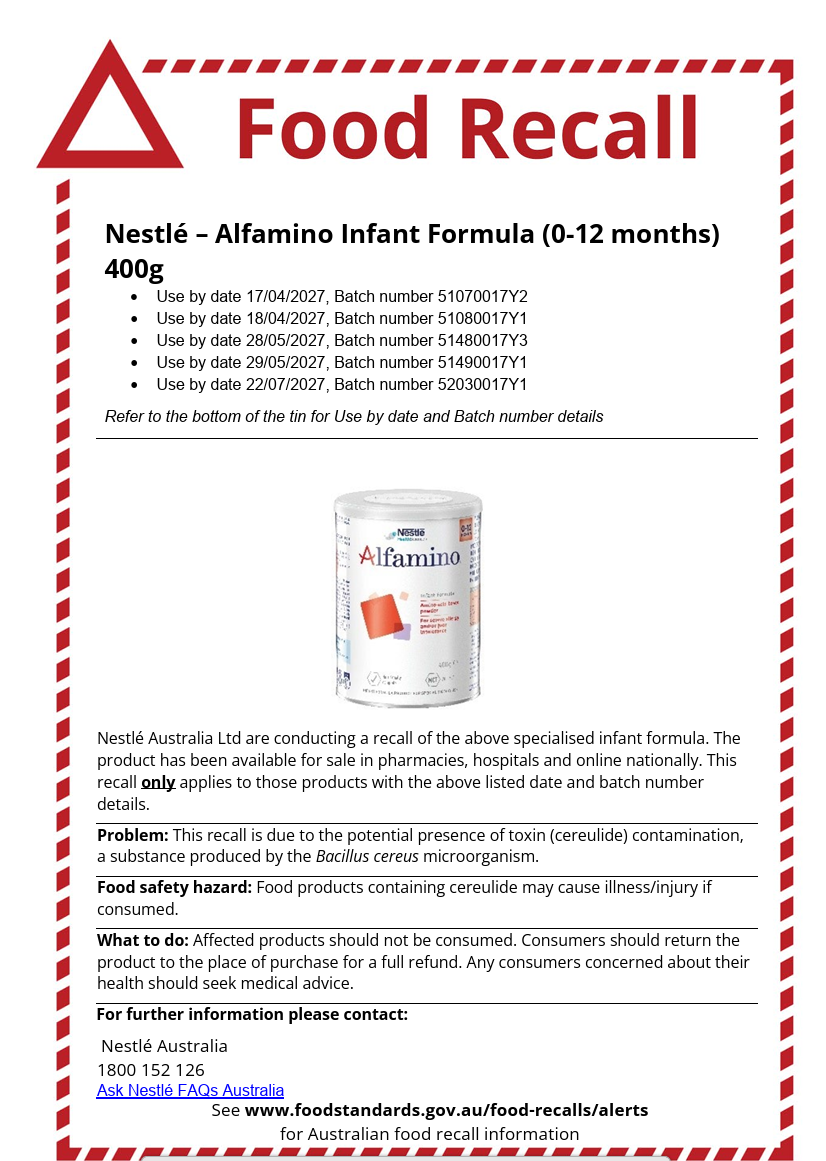

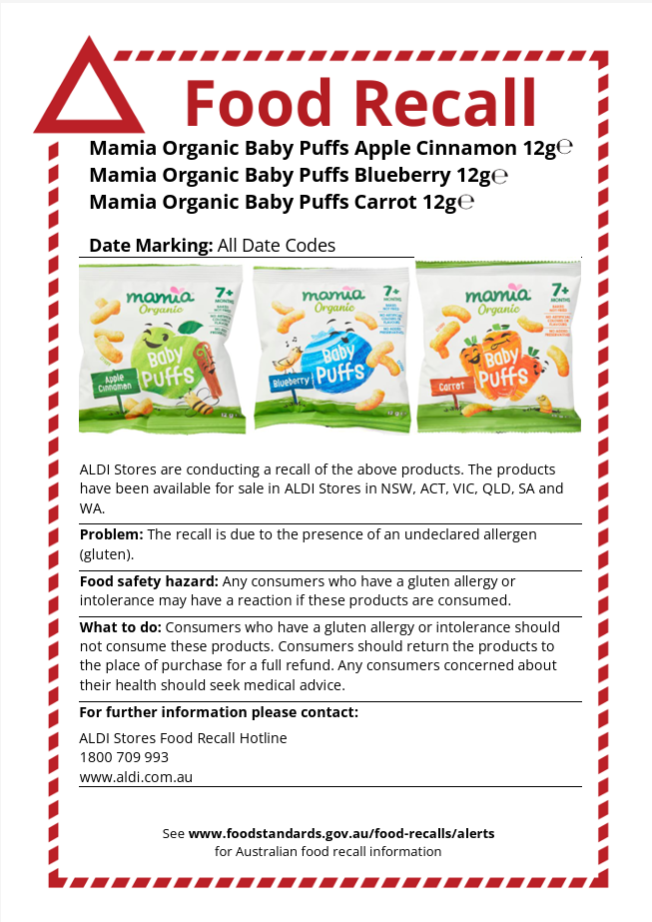

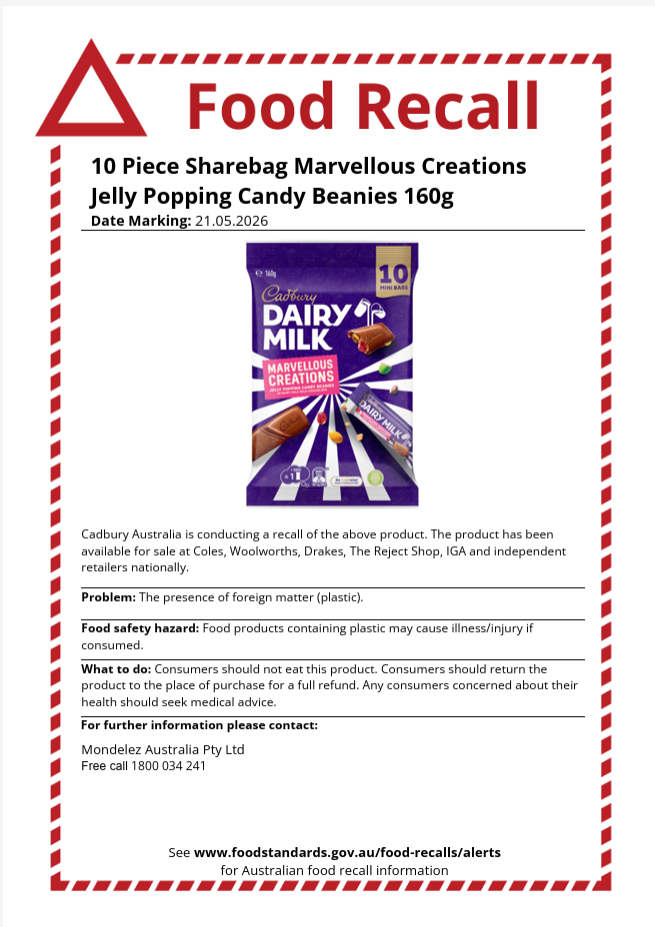

- ISO 22000 objectives should demonstrably reduce food safety risk and improve hazard control effectiveness

- ISO 14001 objectives should focus on material environmental aspects, legal compliance, and impact reduction

- ISO 45001 objectives should prioritise risk elimination, injury prevention, and worker participation

Objectives that no longer influence behaviour or decision-making should be challenged, regardless of past success.

Using Evidence to Recalibrate Objectives

All four standards are grounded in evidence-based decision-making. January provides the most comprehensive dataset to test whether objectives are well designed and appropriately targeted.

Key inputs for review should include:

- Customer complaints, feedback, and satisfaction data

- Food safety incidents, deviations, and verification outcomes

- Environmental incidents, aspect performance, and compliance status

- Health and safety incidents, near misses, and hazard trends

- Internal and external audit findings

- Corrective action timeliness and effectiveness

- Supplier and outsourced process performance

- Management review outputs

Patterns of recurring issues, slow corrective action closure, or repeated audit findings are strong indicators that objectives require recalibration. Equally, objectives that are consistently achieved without intervention may need to evolve from basic control toward resilience, maturity, or continuous improvement.

Strengthening Objective Design Across Standards

While each standard has a distinct focus, the principles of effective objective design are consistent. Strong management system objectives are:

- Outcome-focused rather than activity-based

- Measurable using indicators that enable early intervention, not just end-of-year reporting

- Clearly owned by leaders with authority to influence outcomes

- Resourced appropriately and supported by realistic action plans

- Integrated across disciplines to avoid competing priorities

Where organisations operate an integrated management system, January is the right time to identify overlapping or conflicting objectives and streamline them into a coherent, aligned framework.

Embedding Objectives Into Management and Operations

All ISO standards require objectives to be monitored and updated as appropriate. January sets the cadence for how this will occur throughout 2026.

Effective organisations embed objectives into:

- Management review agendas and executive performance discussions

- Operational planning and departmental KPIs

- Risk registers and change management processes

- Incident, nonconformance, and improvement prioritisation

- Leadership visibility and workforce engagement activities

When objectives are actively used as a management tool, they shift from static metrics to dynamic controls that drive behaviour, accountability, and informed decision-making.

Setting the Tone for 2026

A deliberate, evidence-based review of objectives in January sends a clear message across the organisation: management systems exist to enable performance, not simply to obtain certification.

Organisations that use this moment to reset objectives across ISO 9001, ISO 22000, ISO 14001, and ISO 45001 position themselves ahead of emerging risk, regulatory scrutiny, and operational disruption. More importantly, they ensure their integrated management system remains a strategic asset throughout 2026—supporting confidence, compliance, and continual improvement rather than year-end remediation.